Powder spills everywhere. Packaging is slow. Accuracy? Often a guess. A powder packaging machine changes all that. It’s fast, precise, and clean.

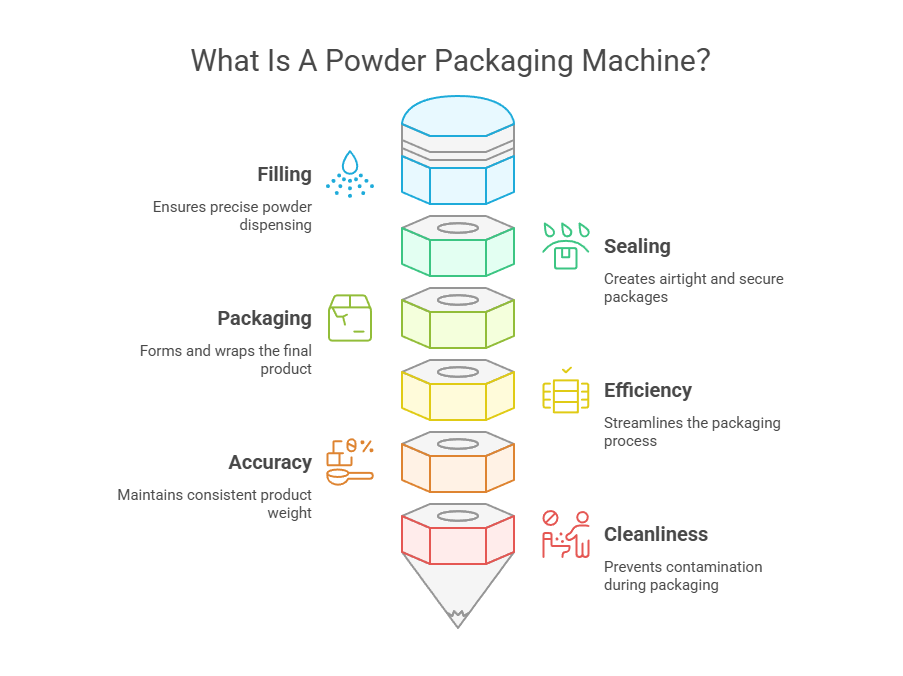

A powder packaging machine is a type of automated equipment that fills, seals, and packages powder products into bags or pouches. It ensures efficiency, accuracy, and cleanliness in powder handling.

Manual powder filling creates bottlenecks in production. It’s messy and inconsistent. I’ve seen manufacturers struggle with labor shortages, product wastage, and customer complaints—all due to inefficient packaging. That’s where powder packaging machines come in. Let me show you what they do, why you need one, and how they can grow your business.

What exactly does a powder packaging machine do?

Packaging powder isn’t like pouring water—it clumps, flies, and sticks.

A powder packaging machine automates filling, dosing, and sealing powder products into pre-formed bags or roll film with precision and consistency.

Key Functions of a Powder Packaging Machine

| Step | Action | Why It Matters |

|---|---|---|

| 1 | Powder enters hopper | Stores material for packaging |

| 2 | Dosing system measures powder | Ensures accurate weight |

| 3 | Powder dispensed into bag | Reduces human handling |

| 4 | Sealing & cutting | Protects product and forms uniform packs |

The main goal is to automate what used to take several workers. Some models, like those we offer at Hannpro, can also include date coding, nitrogen flushing, or dust collection features—great for improving shelf life and cleanliness.

Why is it important for powder manufacturers?

Every second counts in production. Every mistake costs money.

Powder packaging machines reduce packaging errors, labor needs, and production downtime—while improving presentation and reliability.

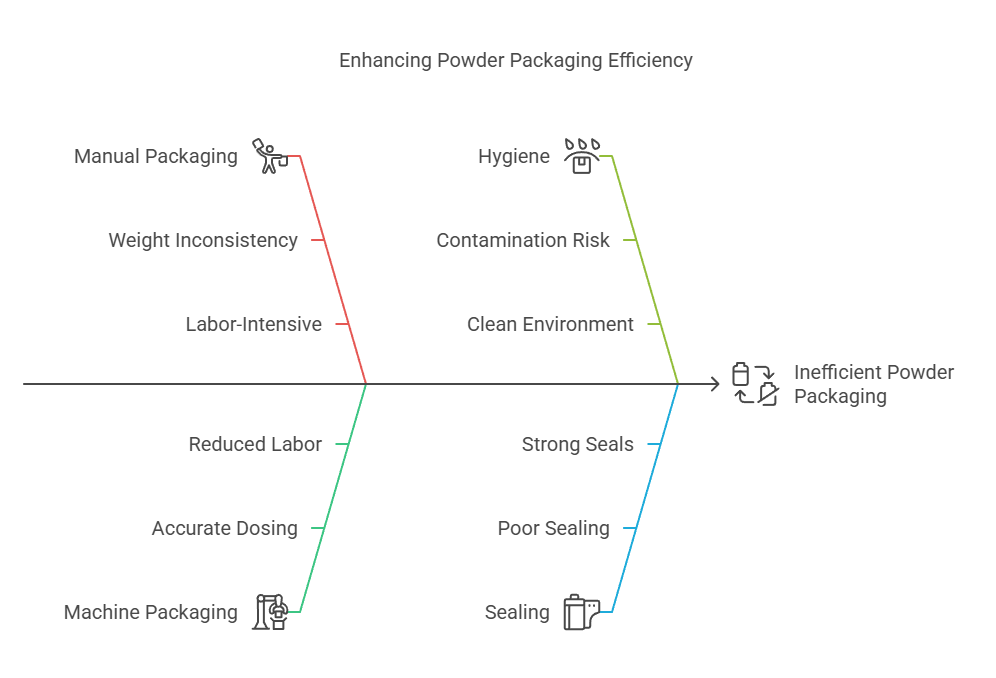

Common Challenges Solved by Powder Packaging Machines

| Problem | Manual Packaging | With Machine |

|---|---|---|

| Weight inconsistency | Frequent over/underfill | Accurate dosing |

| Spillage | High powder loss | Contained system |

| Labor-intensive | Needs multiple workers | 1 operator is enough |

| Hygiene | High contamination risk | Clean, food-grade environment |

| Poor sealing | Bags burst or leak | Strong and uniform seals |

I’ve worked with food supplement clients where a single gram of powder mattered. Manually, it was impossible to hit that accuracy. But once we set up a powder packaging machine, complaints dropped, and our rejection rate went near zero.

What types of powders can be packed?

Not all powders behave the same. Some are free-flowing. Others are sticky or dusty.

Powder packaging machines handle a wide range of powder types—from food and pharmaceuticals to industrial chemicals.

Industries That Use Powder Packaging Machines

| Industry | Example Powders | Notes |

|---|---|---|

| Food | Coffee, milk powder, spices | Requires hygiene & freshness |

| Health | Whey protein, collagen | Needs accurate dose |

| Chemical | Fertilizers, pigments | Demands dust control |

| Pharma | Vitamin powders, supplements | GMP compliance required |

| Cosmetics | Face powder, clay masks | Fills small sachets |

Our stick pack machines at Hannpro work with many of these powders. We also provide auger fillers for non-free-flowing powders like turmeric or matcha. Choosing the right filling method is critical to avoid clogging or jamming.

How does it improve factory efficiency?

More machines, less people? Yes—but smarter, not harder.

A powder packaging machine streamlines your workflow, reduces manpower, and improves packaging consistency—all leading to better profitability.

Cost vs. Return Comparison

| Factor | Manual Process | With Packaging Machine |

|---|---|---|

| Labor cost | High (4–6 workers) | Low (1–2 operators) |

| Speed | 10–20 packs/min | 30–80 packs/min |

| Errors | Frequent rework | Minimal rejects |

| Flexibility | Limited | Easy to switch sizes |

| ROI | Slow | Pays back in 6–12 months |

Let me tell you a story. One of our early clients packaged herbal powder using spoons and funnels. After switching to our Hannpro powder packaging machine, they tripled output and entered supermarkets. That’s the power of automation.

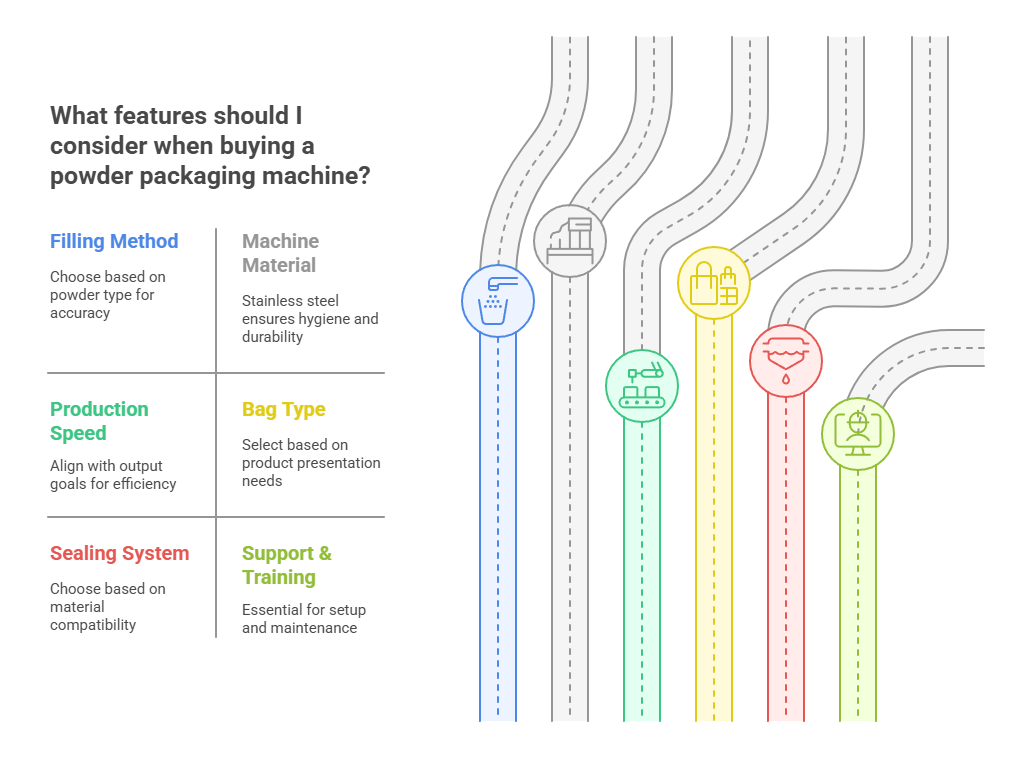

What should buyers look for in a powder packaging machine?

Buying the wrong machine wastes money. You need the right fit.

When choosing a powder packaging machine, check the filling method, bag size range, production speed, and ease of maintenance.

Features to Compare Before Buying

| Feature | Why It’s Important |

|---|---|

| Auger vs volumetric filler | Auger for non-free-flowing, volumetric for dry powders |

| Machine material | Stainless steel for hygiene |

| Speed (packs/min) | Aligns with your output goals |

| Bag type | Stick, sachet, or doypack |

| Sealing system | Heat seal or ultrasonic, depending on material |

| Support & training | Local service reduces downtime |

Machines are not plug-and-play. You need setup, testing, and training. That’s why we provide on-site commissioning and videos for all our Hannpro models.

How to maintain a powder packaging machine?

Ignore maintenance, and your machine will stop working. It’s that simple.

Powder packaging machines need regular cleaning, lubrication, and calibration to maintain accuracy and extend machine life.

Maintenance Checklist

| Task | Frequency | Why It’s Critical |

|---|---|---|

| Clean hopper & dosing area | Daily | Prevents contamination |

| Lubricate moving parts | Weekly | Reduces wear |

| Check seals | Weekly | Ensures tight packaging |

| Calibrate load cells | Monthly | Maintains weight accuracy |

| Replace worn parts | As needed | Avoids sudden failures |

Maintenance is easy when built into your workflow. We always advise clients to train one operator as the “machine owner” to track service logs and monitor performance.

FAQs

1. Can a powder packaging machine handle multiple products?

Yes, most modern machines can store multiple recipes. You can switch between products with minor adjustments.

2. What types of bags can it fill?

Stick packs, pillow bags, sachets, gusseted pouches—depending on the model.

3. Is it suitable for small businesses?

Yes, entry-level machines are compact and affordable, ideal for startups.

4. How accurate are the machines?

Accuracy can reach ±0.2g, depending on powder type and filling method.

5. How much does a powder packaging machine cost?

Basic models start around $5,000. High-speed lines can go up to $50,000 or more.

6. How long does installation take?

Typically 2–5 days, including training and initial testing.

Conclusion

A powder packaging machine simplifies your production, reduces costs, and boosts product quality. If you’re dealing with powders daily, this machine is worth the investment.